Description

This is the machine for the serious cue maker!

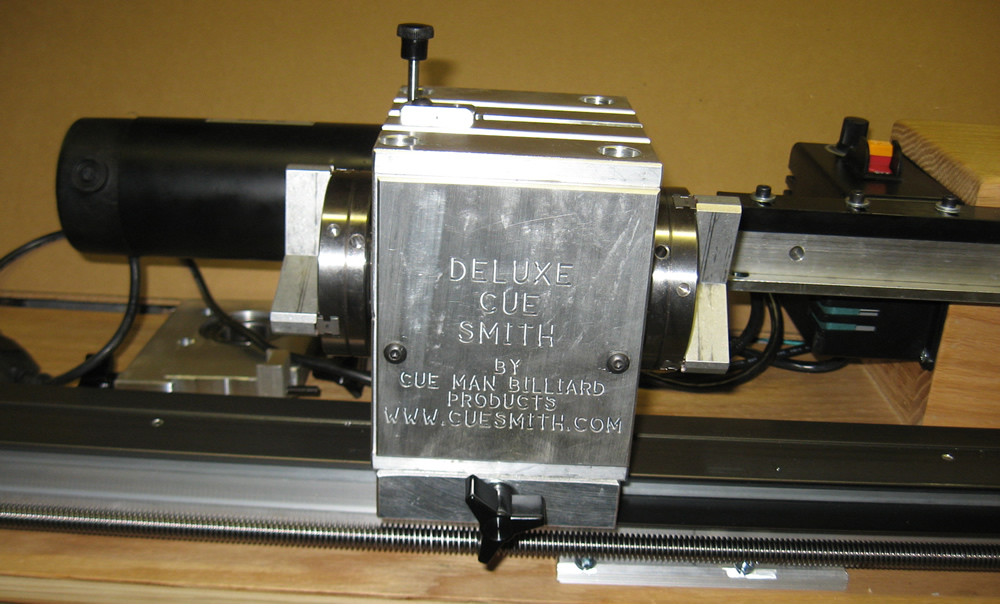

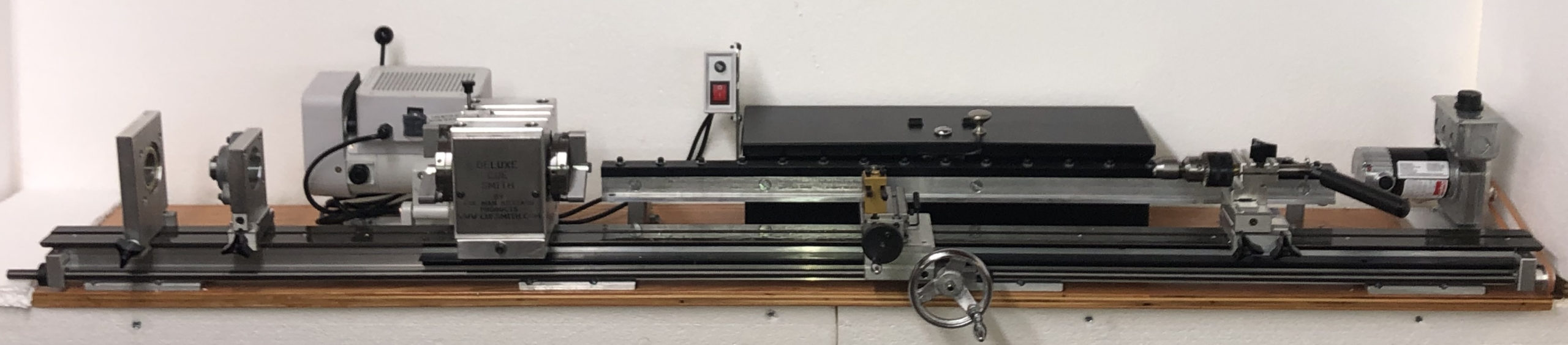

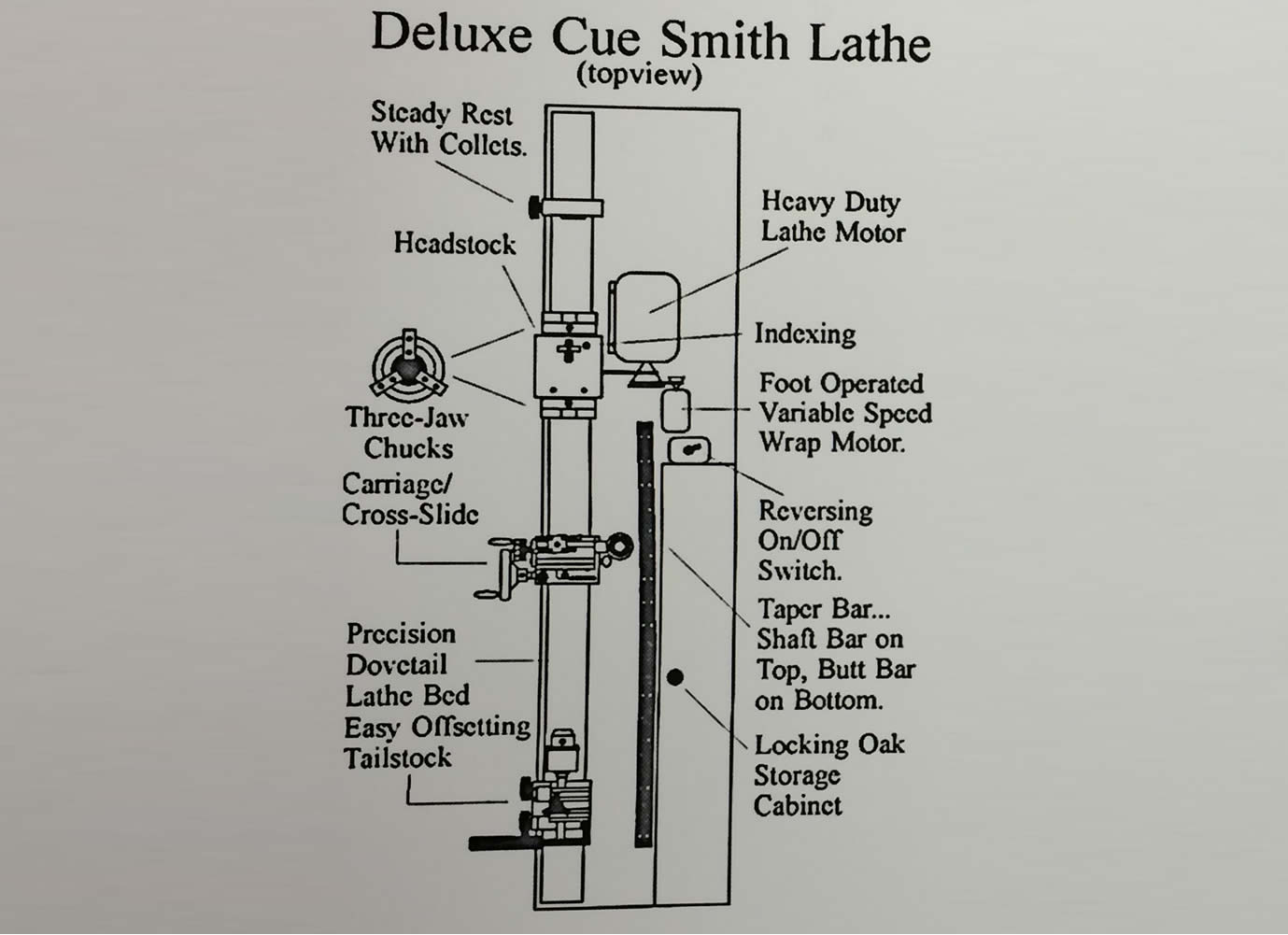

The Deluxe Cue Smith is probably the best cue lathe ever made in its weight and price range. It is about a foot wide and and six feet long and weighs a little over 100 pounds. It has the same precision dove tail bed as the other Cue Smith Lathes. But from there up the Deluxe is heavier made. Instead of the standard 15mm spindle bore, it has a 1-3/8″ plus Spindle bore. It has a triple bearing headstock and uses the larger 2-L belt, which gives it more torque. It has two more inches of swing than the other lathes, and the steady rest has the larger bore also. The collets can be used in the headstock chuck or the steady rest.

If you order the Taper Attachments up front you get a larger handwheel on your carriage. You also get the internal spring loaded, instant touch of a lever access to your taper bars. This makes stainless joints, butts and shafts much easier to taper. You can also make your shaft taper bar removable for an extra $50 and add additional shaft bars for $150 each.

With the optional heavy duty 3/4 HP DC motor you can core, drill, and tap joints and weight bolts under power. Another option is the rear chuck which makes working on the short sections of the cue much faster since you don’t need a collet. Both of the headstock chucks are the same precision speed scroll chucks found on all our lathes, except they have the larger bore. It comes mounted on a oak plyboard and has an optional black metal locking storage box available for an extra $175, and includes a Variable Speed DC motor, wrapping foot control, shaft and butt collets, three lathe pins, two cutting bits, 1/2″ tailstock chuck, concave live center, two 8 ounce shaft cleaner, wax and two hour DVD.

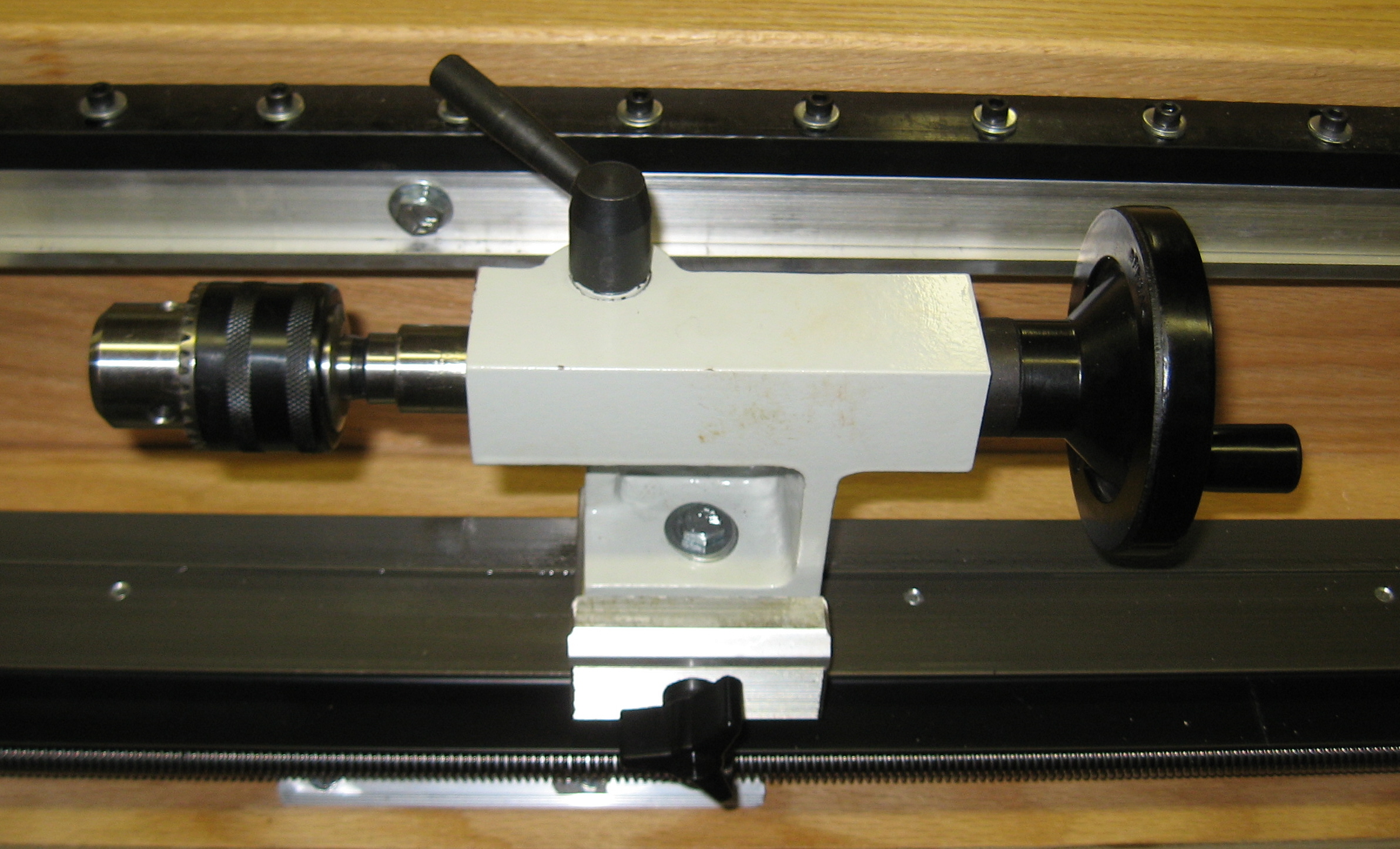

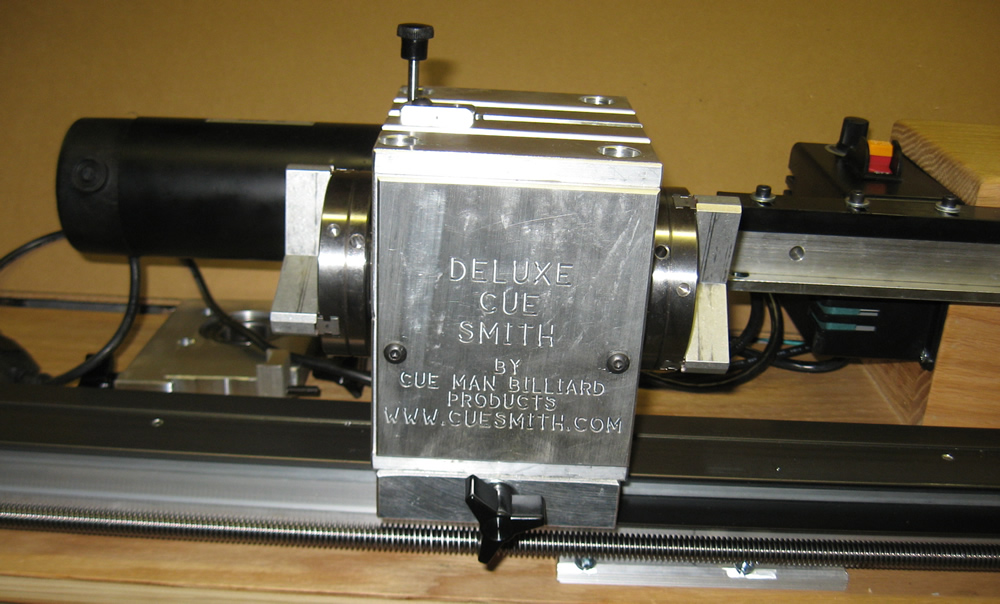

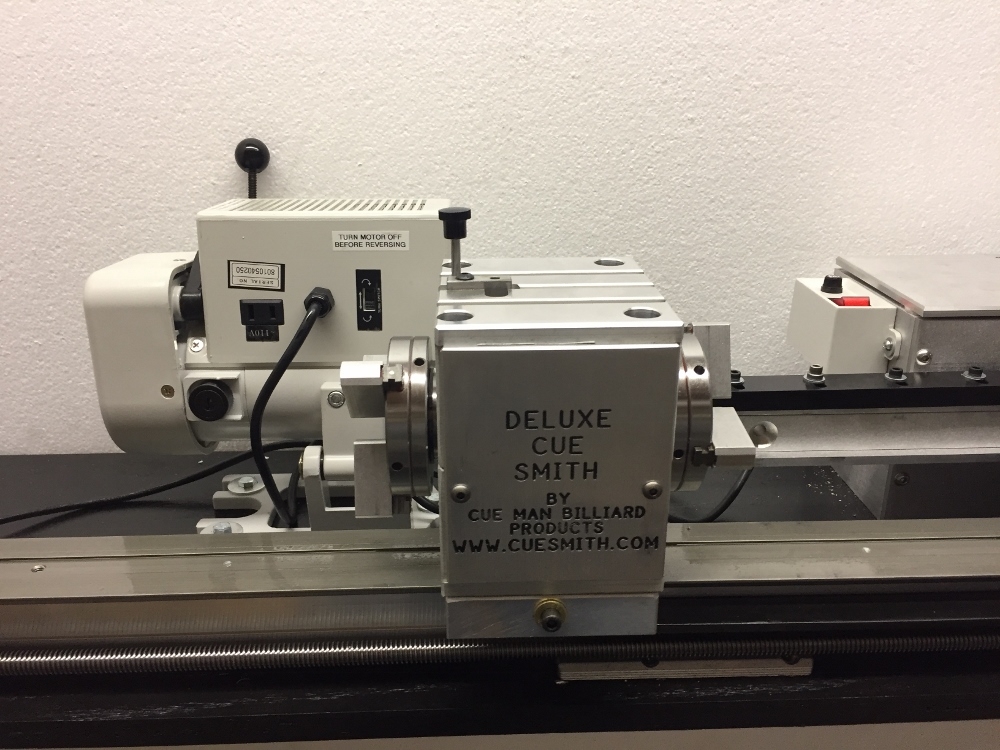

This shows the Deluxe Cue Smith headstock with both chucks, the larger handwheel, and larger tailstock. You can use the steady rest behind or in front of the headstock. The headstock has 24 position indexing for cutting points, slots or inlays.

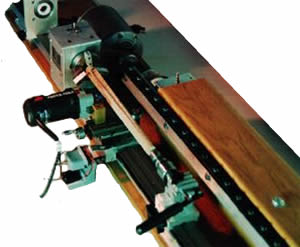

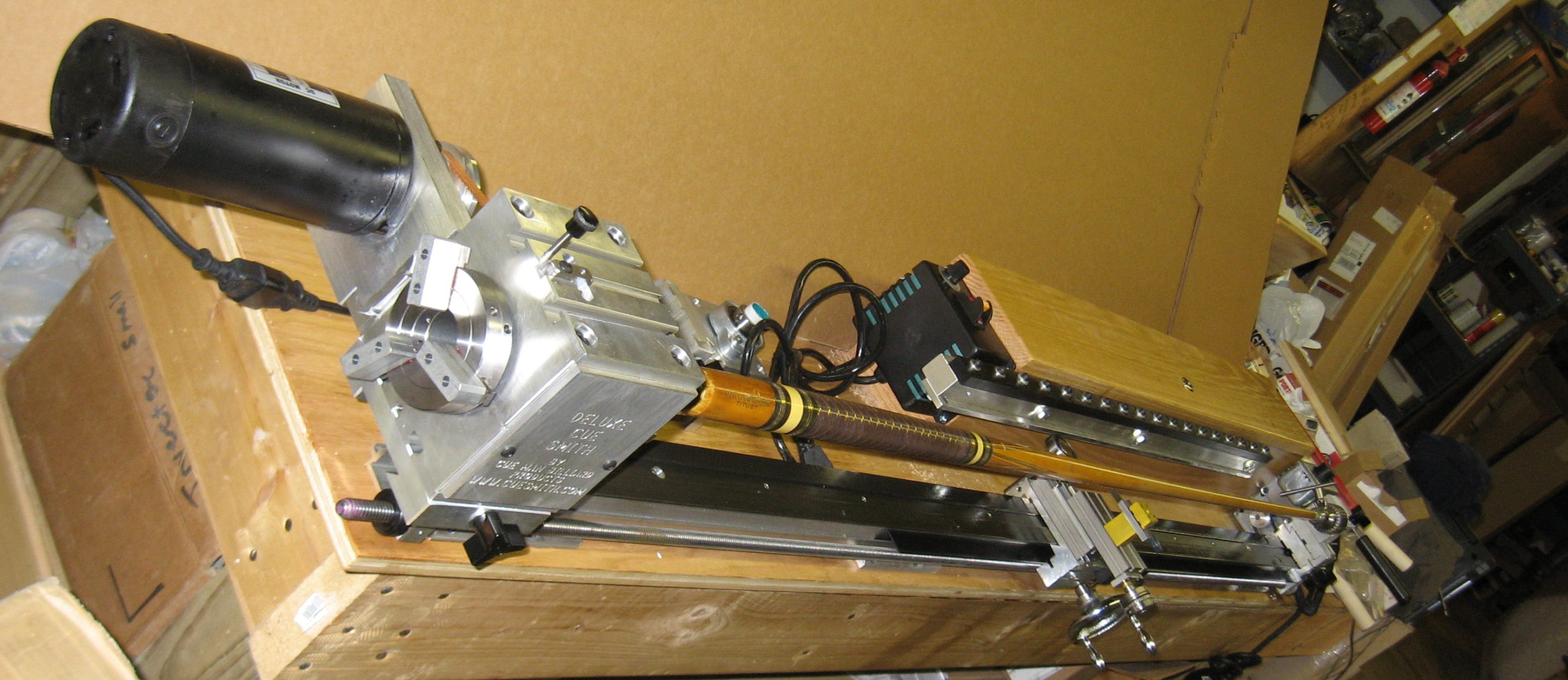

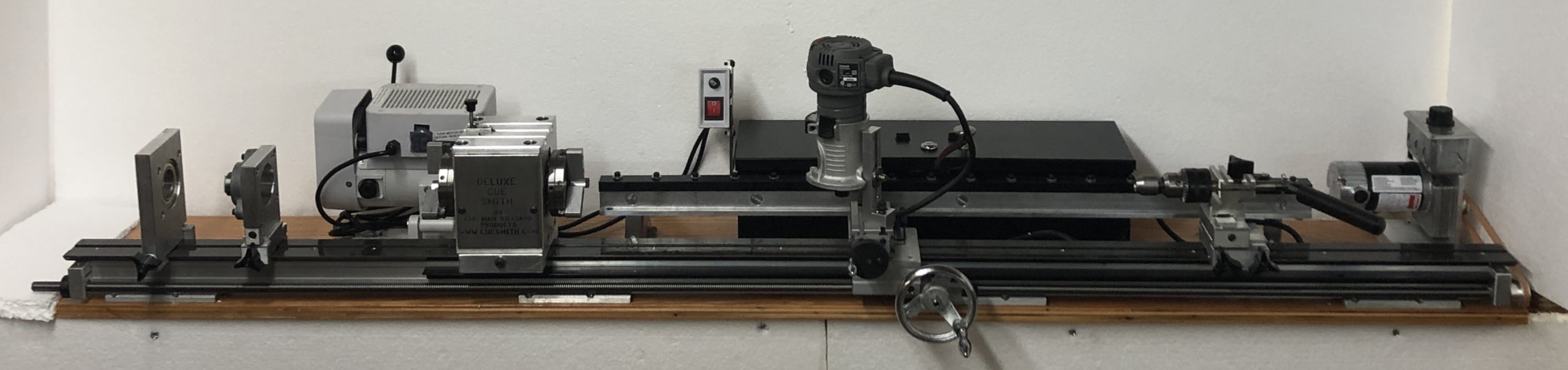

This shows the Deluxe Cue Smith headstock with both chucks, the larger handwheel, and larger tailstock. You can use the steady rest behind or in front of the headstock. The headstock has 24 position indexing for cutting points, slots or inlays. This shows the full length view. Use the router as shown with the taper attachments and power feed to cut shafts and butts with much less vibration than with standard tooling. You can also offset the tailstock to cut a taper or point grooves.

This shows the full length view. Use the router as shown with the taper attachments and power feed to cut shafts and butts with much less vibration than with standard tooling. You can also offset the tailstock to cut a taper or point grooves. This Picture shows the Deluxe Cue Smith cutting in points using the router and power feed.

This Picture shows the Deluxe Cue Smith cutting in points using the router and power feed. This picture shows the Deluxe Cue Smith milling wood threads with the Thread Milling Attachment option. It has the ability to mill inside and outside threads with the included Router and bits. We can also build this with brackets to fit your router which allows use of heavier duty bits (included). With the router you can make clean threads for carom cues or thread on your, butt plates, joints and ferrules. You can even thread the forearm and handle together without having to tap the threads. This is $595 option with one thread pitch for package 2 only..

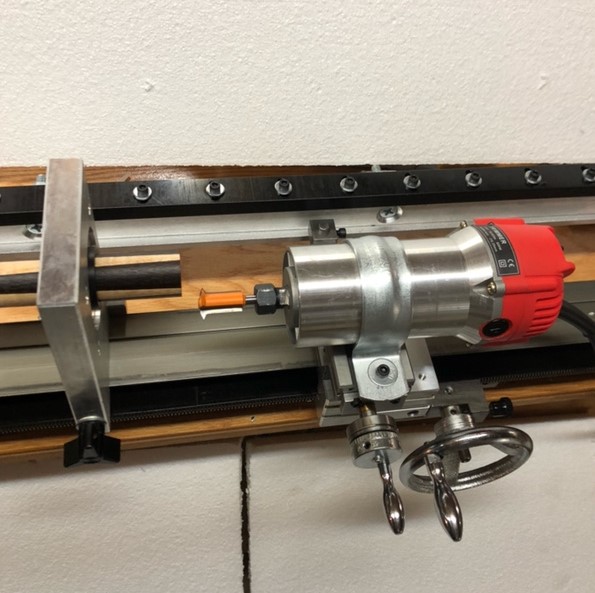

This picture shows the Deluxe Cue Smith milling wood threads with the Thread Milling Attachment option. It has the ability to mill inside and outside threads with the included Router and bits. We can also build this with brackets to fit your router which allows use of heavier duty bits (included). With the router you can make clean threads for carom cues or thread on your, butt plates, joints and ferrules. You can even thread the forearm and handle together without having to tap the threads. This is $595 option with one thread pitch for package 2 only.. The variable speed sliding headstock option and lead screw power feed.

The variable speed sliding headstock option and lead screw power feed. To the left shows the package 2 Deluxe turning a one piece cue between centers.

To the left shows the package 2 Deluxe turning a one piece cue between centers. #2 Morse Taper Tailstock. Not a replacement for the Speed Lever Tailstock, but a great second tailstock for drilling larger holes. $225 optional.

#2 Morse Taper Tailstock. Not a replacement for the Speed Lever Tailstock, but a great second tailstock for drilling larger holes. $225 optional.

pjchc -alaska- –

My passion so far, does not include C.N.C.

Have used the early deluxe model since later 2005. Great hand operated machine.

david –

usefull

still my primary work horse

Pete Kasameyer –

I purchased my (well used) Deluxe Cue Smith lathe with a package of tooling and cue building equipment, wood and supplies about 6 years ago from a third party seller. Included was an early version of Chris’s book and several DVD’s of his 90’s era VHS instructional videos.

I have no prior machining or lathe experience but have been a hobbyist woodworker all my life. SO, I was a typical NOOB to cue work.

With this lathe and documentation, I was able to learn very quickly how to do basic cue building operations such as cutting accurate and concentric mortise and tenon, drilling and threading, putting in pins correctly, making rings, tapering etc. The equipment is precise and repeatable, and is sole purpose designed and built for cue making. I was able to build very nice (straight) high performance cues with wraps, rings etc. in a very short time.

I recently retired and now use this machine every day to build and repair cues. It is very solidly built and has withstood a lot of my learning curve mistakes without breaking. You can do anything you need to do on a cue with this machine and the available accessories.

Chris and his team’s level of customer support is unmatched. He is very responsive and supportive on internet forums. I have never had a need to call him for help as everything you need to know is in his documentation or quickly found with a google search. As we used to say in the military, RTFB!

I ordered a lathe belt from him on Tuesday and and received it on Wednesday, standard shipping. Granted, I live in the same state (Ga.) but several hours away. It just shows how quickly they respond to their customers and get orders out the door.

I give Chris and his team my highest possible recommendation.

Pete

Precision Cue Service